⬇︎Click on any photo, below, to open slide show. Use keyboard arrows or swipe to view slides.

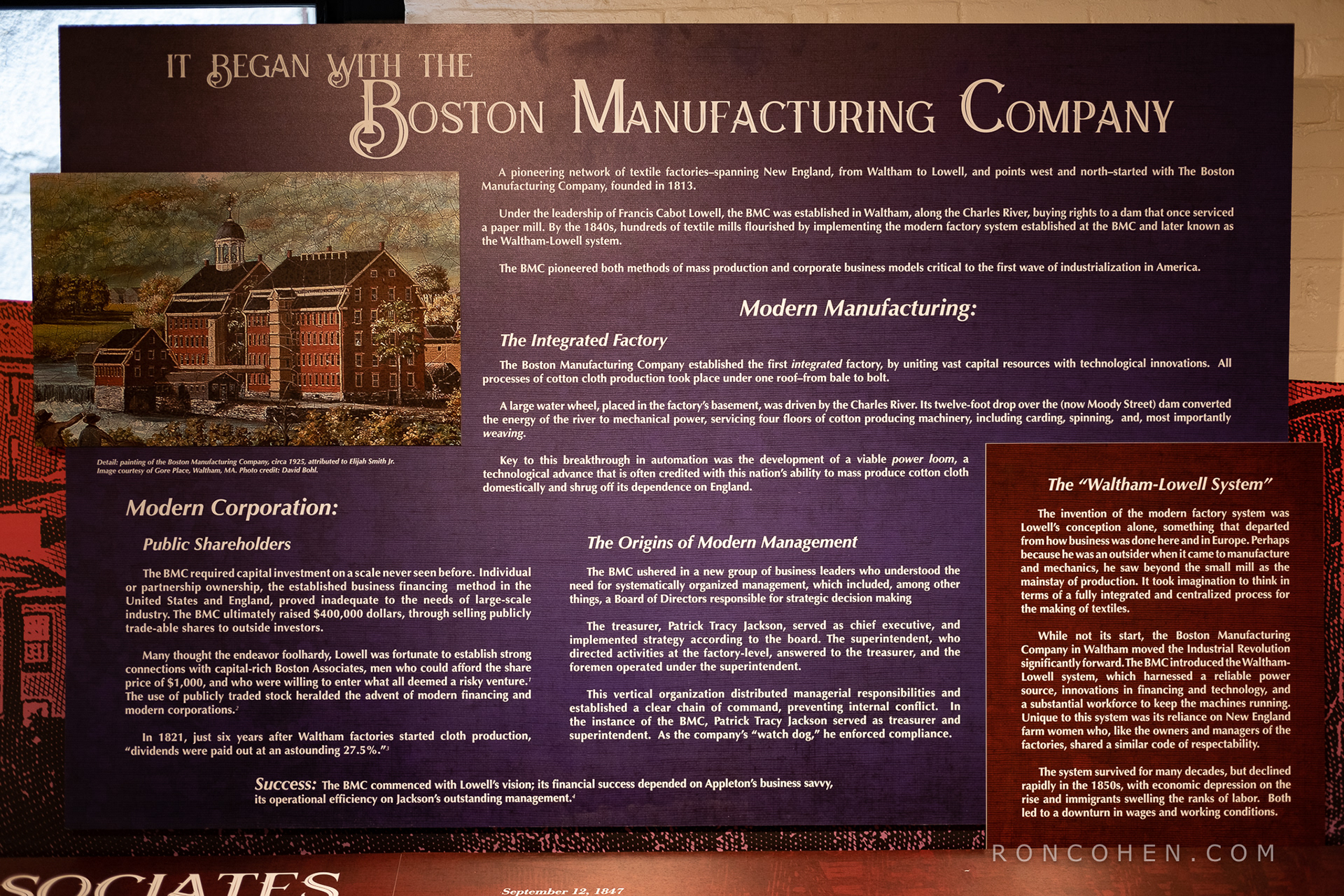

Francis Cabot Lowell founded the Boston Manufacturing Company, in Waltham, in 1813. It housed all the operations for producing finished fabric under one roof, making it the most advanced textile mill in the United States at the time. In modern terms it would be described as vertically integrated: raw cotton entered at one end and finished fabric came out the other. At its heart was Lowell’s brainchild, a water-powered loom, perfected by a self-taught genius, Paul Moody.

Boston Manufacturing was the first, modern industrial corporation in America, setting standards of capitalization, management, technology and labor organization that served as a model and a spur for the country's nascent industrial revolution. Young farm girls were recruited as the workforce, and were housed in dormitories nearby. They were well paid, in cash, giving them a new-found independence, despite the long hours and regimented living.

To achieve his vision, Lowell assembled a small group of well-connected Boston businessmen who later came to be known as the "Boston Associates." They combined technological innovations, new business strategies, and a shared sense of social responsibility to create the Waltham-Lowell system of manufacturing—so-named as it eventually extended to Lowell and Lawrence, Massachusetts; Manchester, New Hampshire; and Saco, Maine.

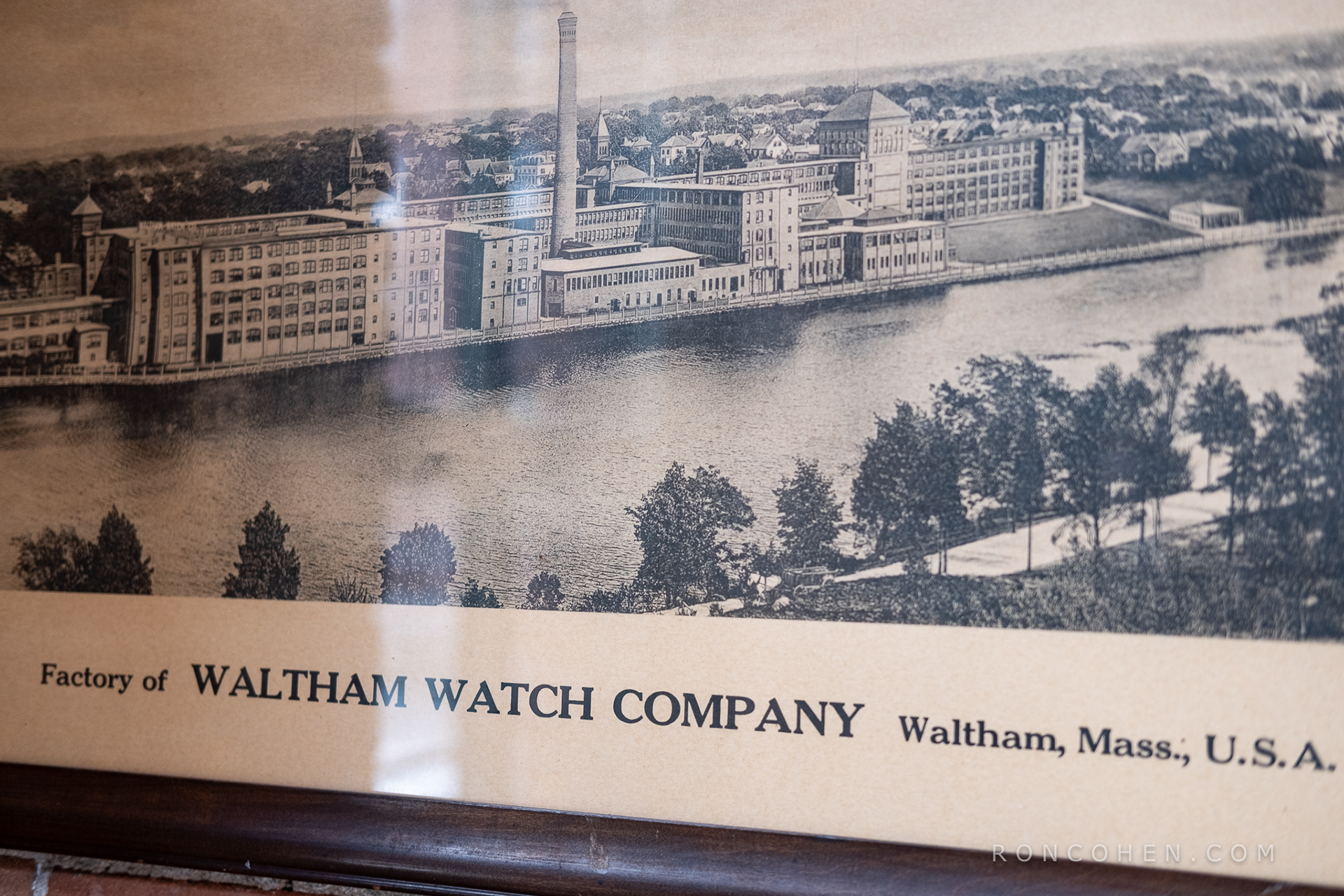

In the 20th Century, the mill buildings were converted to elderly apartments. At the back of the complex is located the Charles River Museum of Industry & Innovation. This small gem of a museum traces the industrial revolution in America from 1813 through mid-20th Century. Showcased are many pioneering Waltham companies, among them the famed Waltham Watch Company.

The photos above are arranged in three parts: 1) the mill buildings’ exterior, today, 2) the BMC exhibits, and 3) a few of the many other museum exhibits. (More information about the other exhibits can be found on the museum’s website, here.) Following is a breakdown of what’s shown in the latter two parts:

BMC Exhibits: A big blue sign explaining why the BMC was historically so important (click or tap twice on this image to enlarge it). A working model of the famous power loom. A big bell that controlled the workers’ daily schedule. A diorama showing the first two mill buildings along the river, and dormitories for the farm-girl workers nearby.

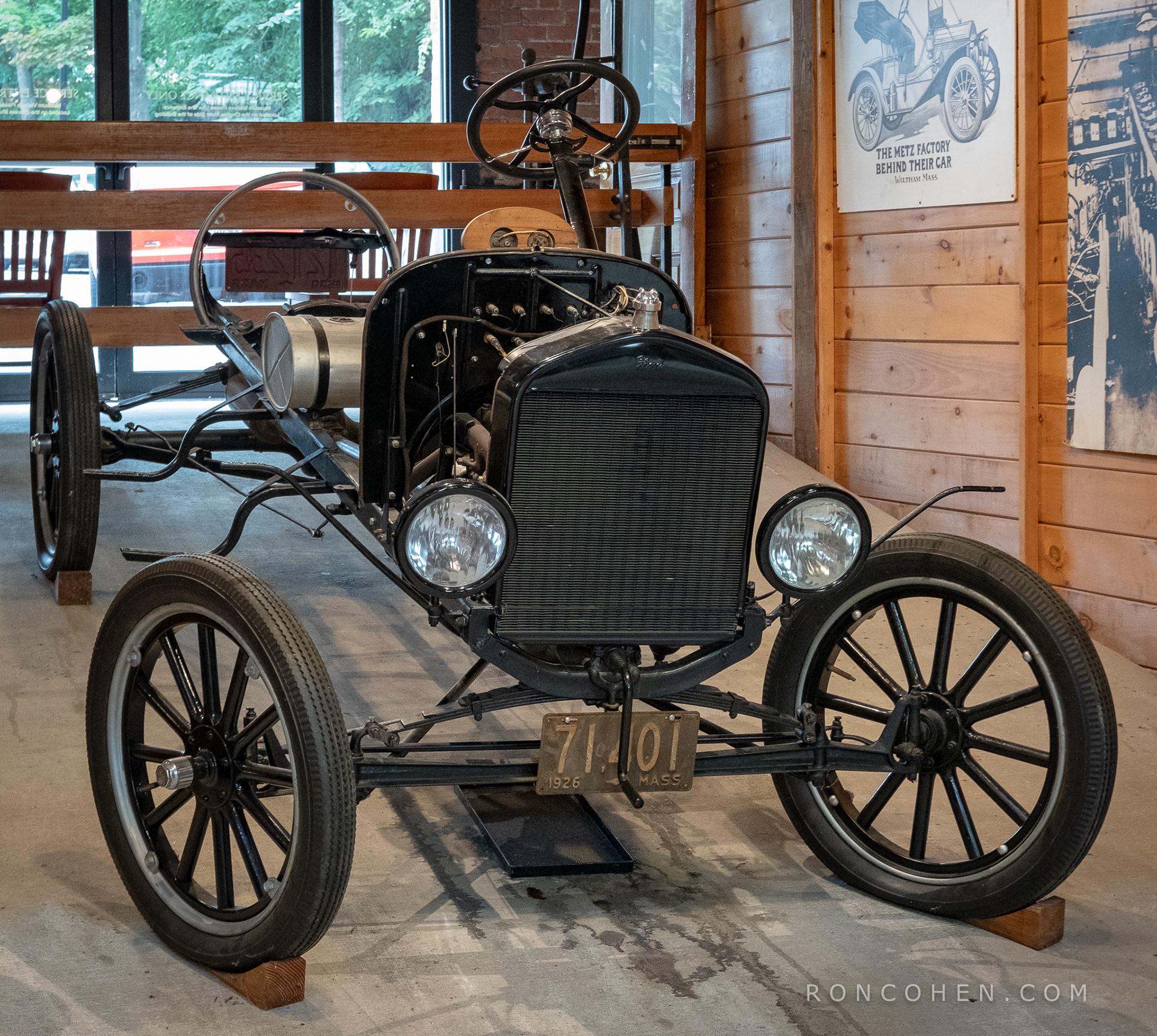

Other Exhibits: A 1920 paper bag machine that produced 22,000 bags an hour for the Waltham Paper Bag Company. An 1857 horse-drawn fire engine with a steam powered tank, which shot water through the hoses to a height of 150-200 feet. A fully intact Model T chassis. Finally, an engraving machine from the Waltham Watch Company (1854-1950), and a few of its mass-produced watches and clocks.

As I went about taking pictures, I noticed various antique machines and machine parts lurking in corners of the museum, which I felt were of visual interest in their own right. I have posted photos of them as a separate story at Machinery.